Litian provides a series of specifications and performance disc cutter rings to meet the requirements of various geological applications and to allow the cutters to give full play to their best performance. We have conducted in-depth research on the material of the cutter ring and processed it with different strengths, so that the hardness of the cutting blades reaches HRC60, and the service life is increased by 30%~50%.

Specification | 12 inch (305mm) | 15.5 inch (394mm) | 17 inch (432mm) | 18 inch (457mm) | 19 inch (483mm) | 20 inch (508mm) |

Application Range (Cross-section Diameter) | 2~3m | 3~5m | >5m | >6m | >8m | >10m |

Optional Cutter Rings | Description |

Standard Cutter Ring | Standard disc cutter ring is suitable for drilling 50~150Mpa conglomerate, marble, sandstone, and limestone formations. |

HD Cutter Ring | Heavy duty disc cutter ring is suitable for tunneling 120~250Mpa hard rock, and 80~150Mpa high-wear rock strata, such as granite, diorite, porphyry, serpentine, and basalt. |

TCI Cutter Ring | Tungsten carbide inserts disc cutter ring is suitable for excavating tight strata of 40Mpa, fractured conglomerate, sandstone, sandy clay and other strata of 80-100Mpa. |

Cutter Ring Blade Shapes | Introduction |

Flat Blade Cutter Ring |

Mainly used for standard cutter rings, suitable for rocks with low uniaxial compressive strength.

|

Arc Blade Cutter Ring | The effect of breaking hard rock is better, and it is mostly used for heavy-duty cutter rings, suitable for hard rock with higher strength. |

Chisel Blade Cutter Ring | The effect of breaking hard rock is good, and it is mostly used for heavy-duty cutter rings, suitable for hard rock with high strength. |

We can recommend disc cutter rings of different designs and production processes according to the rock working conditions and the arrangement of cutter heads to better meet customer needs.

Litian disc cutter ring is made of high-quality mold steel, containing CR, MO, V, NI, and other alloy elements. It has high wear resistance, good impact resistance, good hardenability, and strong hardness, which can make the whole disc cutter has strong physical and mechanical properties. We have combined the characteristics of various rock conditions in each project to develop standard cutter rings and heavy-duty cutter ring materials. Using refining outside the furnace and electroslag remelting smelting process to reduce the content of harmful substances sulphur and phosphorus, and improve the performance of the material.

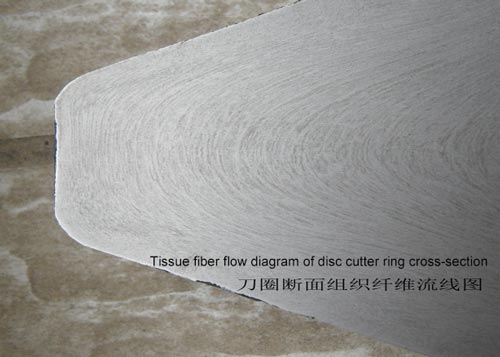

We use the ring forging process (rolling forming) to ensure that the tissue fibers become continuous streamlines, improving the strength and wear resistance of the material, while the ordinary die forging metal tissue fiber streamlines are discontinuous, prone to chipping and breaking.

We use vacuum furnaces imported from Germany for heat treatment to avoid carbon precipitation on the surface. The reasonable heat treatment process makes the crystal grains fine, and the fine spherical alloy carbides are evenly distributed.

Jan 23-2026

How to Choose the Best Drill Rod Factory

Jan 18-2026

Core Drilling in Mining vs Construction