Litian can produce and supply matching shank adapters for most rock drills on the market. Our products can meet the harsh operating environment and use in different construction conditions.

Our rock drilling shank adapters are available for:

Material:Structural Alloy Steel (23CrNi3Mo, Optional high quality imported material)

Application:Tunnelling , Mining , Quarrying, Blasting and Infrastructure Construction

Processing:CNC and heat treatment process

Shank Type:Male shank adapter, Female shank adapter

Thread:R25, R28, R32, R35, R38, T38, T45, T51, GT60, ST58, ST68

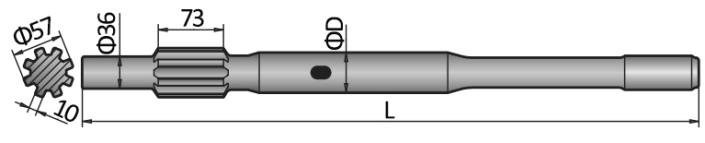

Diameter:32mm~90mm

Length:370mm~835mm

Custom Design:Acceptable

We supply the best T38 T45 Shank Adapter for Drill for Furukawa HD609 rock drill, which can be widely used in bench drilling.

| Thread | Length [mm] | Diameter [mm] | Splines | Weight [kg] | Model No. | Similar Part No. |

| T38 | 690 | 45 | 8 | 6.3 | T38*8D45-690 | 7304-4780-01 90516197 |

| T45 | 620 | 45 | 8 | 6.4 | T45*8D45-620 | 7305-4791-01 90510276 |

| T45 | 690 | 45 | 8 | 6.8 | T45*8D45-690 |

Jan 23-2026

How to Choose the Best Drill Rod Factory

Jan 18-2026

Core Drilling in Mining vs Construction