TBM disc cutter is a disc-shaped roller cutter mounted on the cutterhead of tunnel boring machine, which is an excavation tool for breaking hard rocks. The type of disc cutters, in different sizes and specifications, can be mounted on the cutter heads of large trenchless construction equipment such as TBM, shield machine, MTBM, pipe jacking machine, SBU (Small Boring Unit), shaft boring extension machine, and are widely used in subway tunnels, railway tunnels, diversion tunnels, urban underground pipe network construction, mining and other industries.

Litian has been conducting research on the materials, heat treatment process and manufacturing process of the TBM disc cutter components, combined with on-site testing to make improvements. As a result, the TBM disc cutters produced by Litian heavy industry has been in a leading position in the industry in terms of wear resistance, high temperature oxidation resistance, toughness. Litian TBM roller cutter can adapt to the needs of multiple types of engineering, and can meet the requirements of long-distance excavation under the compound strata of highly weathered rock, moderately weathered rock, slightly weathered rock, and has good stability and reliability.

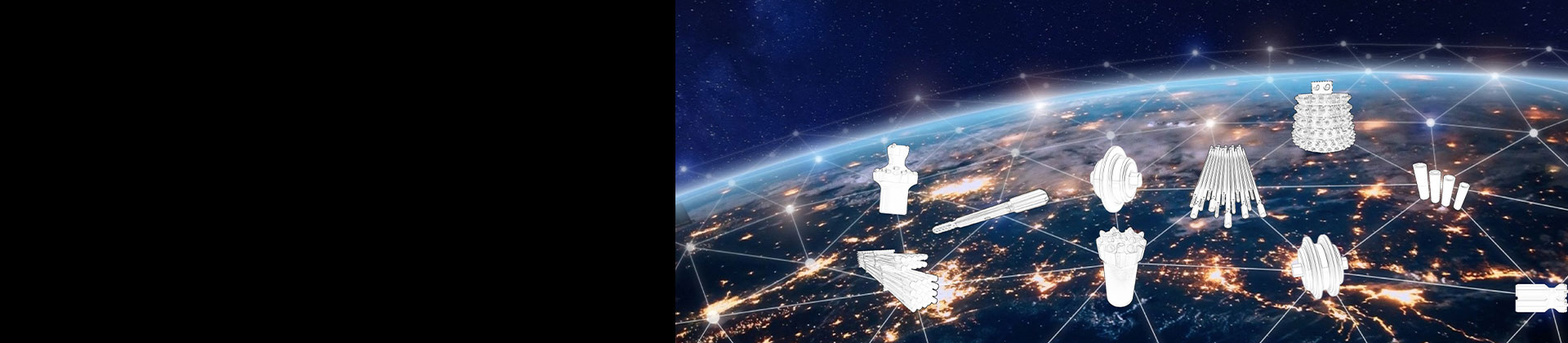

Single disc cutter is usually mounted on the face area and gauge area of cutter head. It is mostly used to break mixed ground and hard rock with high uniaxial compressive strength.

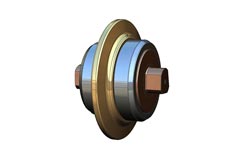

Double disc cutter is usually mounted on the face area and gauge area of cutter head, and is mostly used to break mixed ground and rock with low uniaxial compressive strength.

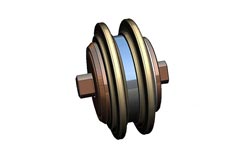

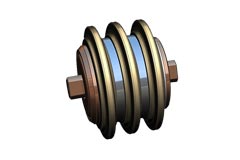

Twin disc cutter is mounted on the center area of TBM cutter head, and is mostly used to break mixed ground and hard rock.

Triple disc cutter is mainly used on micro-tunneling equipment and can be mounted at any position on the cutter head as required.

TBM disc cutter ring is an indispensable part of the rolling disc cutter, and it is the first component that comes into contact with the rock.

Disc cutter is assembled from many components, such as cutter ring, hub, bearing, shaft, floating seal, end cover, etc.

Cutter Type | Diameter | Bearing Capacity [tonne] | Structure | |

[inch] | [mm] | |||

20" | 508 | 35, 42 | Monoblock / Assembly | |

19" | 483 | 35, 42 | Monoblock / Assembly | |

18" | 457 | 28 | Monoblock / Assembly | |

17" | 432 | 28, 32(single disk) | Monoblock / Assembly | |

15 1/2" | 394 | 22 | Monoblock / Assembly | |

Single Disc Cutter Double Disc Cutter | 12 1/2" | 320 | 16 | Monoblock / Assembly |

12" | 305 | 16 | Monoblock / Assembly | |

11" | 280 | 13 | Monoblock / Assembly | |

10" | 250 | 10 | Monoblock / Assembly | |

9" | 220 | 9 | Monoblock | |

8" | 200 | 8 | Monoblock | |

7" | 180 | 8 | Monoblock | |

6 1/2" | 165 | 5 | Monoblock | |

6" | 150 | 4 | Monoblock | |

Center Disc Cutter | 18" | 457 | 42 | Assembly |

17" | 432 | 45 | Assembly | |

15 1/2" | 394 | 45 | Assembly | |

13" | 330 | 40 | Assembly | |

12" | 305 | 35 | Assembly | |

Manufacturing technique: Our advanced CNC machine tools can ensure the consistency of the size of the cutter components. Combined with strict and standardized assembly process to ensure the torque of the disc cutter. Adjust the torque in an appropriate range, so that it can well meet the requirements of the surrounding rock geology for the starting torque of the disc cutter, which is helpful to avoid partial wear of the disc cutters in different strata. We have a unique heat treatment process, which can meet the unity of wear resistance and toughness, and improve the service life of the disc cutter.

Sealing system: The sealing system of our disc cutter adopts the world famous brand metal sealing system. During the assembly of the disc cutter, the distortion of the rubber ring may lead to air leakage, and this hidden danger is difficult to detect. We use special technology to assemble the disc cutter to correct the distortion of the rubber ring, eliminate the hidden danger of metal seal air leakage, and ensure the sealing reliability of the disc cutter.

Bearing system: Our disc cutter bearings are heavy-duty tapered roller bearings, which can bear the combined radial and axial load strength at the same time.

TBM disc cutter is pressed on the rock surface to be broken by the hydraulic system of the machine. In the process of working, the disc cutter rotates around its own axis, and at the same time it revolves around the central axis of the cutter head as the cutter head rotates. Under the combined action of the rotating torque of the cutter head and the vertical thrust of the propulsion cylinder, the disc cutters distributed on the cutter head cut out a group of concentric circles on the tunnel face. When the compressive strength of the rock is lower than the thrust of the cutter head, the rock will be directly broken by the cutter blade, thus forming multiple concentric grooves. With the advance of the cutter head, the groove depth gradually deepens, and the blade penetrates into the rock, forming crushing zones and radial cracks. Under further pressure, when the hob spacing meets certain conditions, the surface crack of the adjacent rock mass expands gradually, and finally the rock between the adjacent concentric grooves collapses, and the rock breaking process of the disc cutters is completed.

In the case of normal wear, we recommend that the disc cutter needs to be replaced when the cutter ring of gauge cutter is worn out about 10-15mm, and the cutter ring of face cutter and center cutter is worn out about 20-25mm. At this time, the cutting edge of the cutter ring becomes wider and its ability to cut rocks is reduced. The torque and thrust required for TBM tunneling will increase, which increases the load of the TBM hydraulic system and motor system, and the crushed rock will also wear the cutter head, thereby reducing the service life of the TBM.