Single Disc Cutter | Diameter | Bearing Capacity [Tonne] | Cutter Ring | Structure | |

Product | [inch] | [mm] | |||

| 20" | 508 | 35, 42 | Optional | Assembly |

19" | 483 | 35, 42 | Optional | Assembly / Monoblock | |

18" | 457 | 28 | Optional | Assembly / Monoblock | |

17" | 432 | 28, 32 | Optional | Assembly / Monoblock | |

15 1/2" | 394 | 22 | Optional | Assembly / Monoblock | |

14 | 356 | 20 | Optional | Assembly / Monoblock | |

12" | 305 | 16 | Optional | Assembly / Monoblock | |

11" | 280 | 13 | Optional | Assembly / Monoblock | |

10" | 250 | 10 | Optional | Assembly / Monoblock | |

9" | 220 | 9 | Optional | Monoblock | |

8" | 200 | 8 | Optional | Monoblock | |

7" | 180 | 8 | Optional | Monoblock | |

6 1/2" | 165 | 5 | Optional | Monoblock | |

6" | 150 | 4 | Optional | Monoblock | |

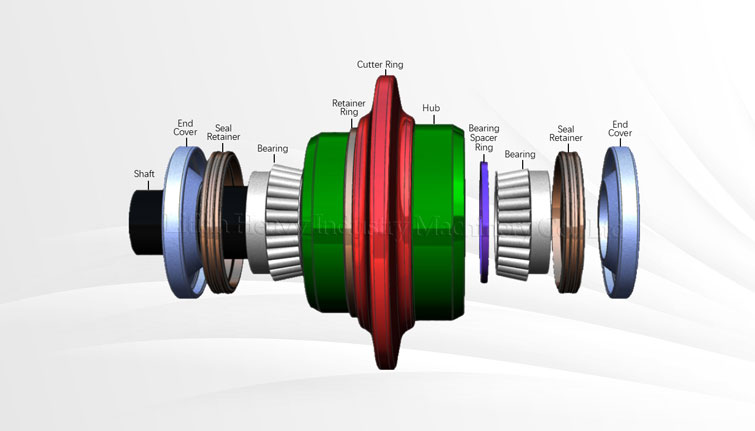

Single disc cutters are primarily used in tunnel boring machines (TBMs) for excavating through various types of geological formations, ranging from soft soil to hard rock. These cutters are mounted on the cutter head of the TBM and rotate as the machine advances, applying concentrated force to the tunnel face to break and remove the material. The design and material of the cutter disc are tailored to match the specific hardness and abrasiveness of the rock or soil being excavated.

The effectiveness of single disc cutters is largely dependent on their ability to fracture the rock in front of the TBM through a rolling action. As the cutter head rotates, each disc cutter exerts a high-pressure force on a small area of the rock surface, causing cracks to form and propagate. Over time, these cracks lead to the fragmentation of the rock, allowing it to be removed and transported out of the tunnel.

Single disc cutters are crucial for the efficiency and progress of tunneling operations. They are designed to withstand extreme pressures and abrasive conditions, and their performance can significantly impact the speed and cost of tunnel construction projects. Proper selection, maintenance, and replacement of these cutters are essential for minimizing downtime and ensuring the smooth operation of the TBM.

Jan 23-2026

How to Choose the Best Drill Rod Factory

Jan 18-2026

Core Drilling in Mining vs Construction