Cross-type drill bits are specialized tools designed for drilling through hard and abrasive rock formations, making them a top choice for professionals seeking the best drill bit for hard stone. Their chisel-shaped design excels in challenging conditions, ensuring efficient rock drilling in mining and quarrying. This article explores how to drill rock using cross-type drill bits, their features, applications, and maintenance strategies, highlighting their role in drilling holes in rocks.

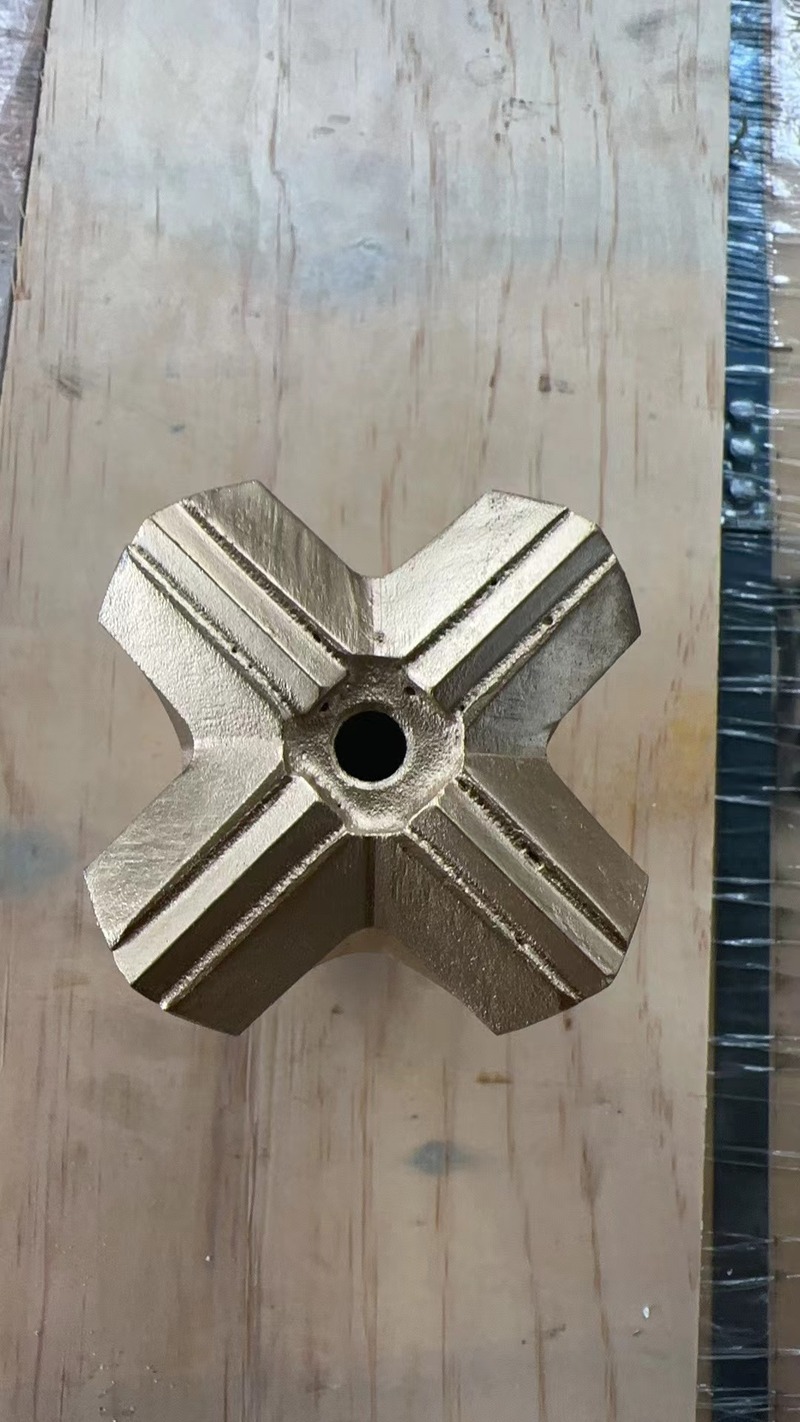

Cross-type drill bits feature a chisel-shaped tip made from tungsten carbide, forming a cross pattern that enhances cutting efficiency in hard rock abrasive formations (Epiroc, 2019). Used primarily with hammer drills, these bits are ideal for drilling rock with a hammer drill, particularly in deep-hole applications like quarrying or mining blast holes. Available in diameters from 30–100 mm, they are designed to withstand intense wear, making them suitable for drilling through hard stone like granite or quartzite (Wittig, 2017).

The cross design distributes impact forces evenly, reducing bit wear and ensuring stable performance when drilling into rock with high abrasion.

Cross-type drill bits are used in:

Quarrying: Drilling deep holes for rock splitting or explosive placement.

Mining: Creating blast holes in hard rock formations for mineral extraction.

Construction: Drilling a hole in a rock for anchoring or foundation work.

Geotechnical Studies: Penetrating abrasive rock for subsurface analysis.

Litian Heavy Industry’s cross-type drill bits, with robust carbide tips, ensure reliable performance in abrasive quarrying projects.

Wear Resistance: Tungsten carbide tips withstand abrasive conditions, making them the best drill bit for rocks in high-wear environments (Holmberg et al., 2017).

High Impact Efficiency: The cross-shaped design delivers strong cutting force, ideal for drilling through hard stone.

Stability: Reduces bit wandering, ensuring precise drilling a hole in rock.

Versatility: Suitable for deep-hole drilling in both surface and underground applications.

To maintain cross-type drill bits:

Inspect Tips: Check tungsten carbide tips for wear or chipping after each use (American Pneumatic Tools, n.d.).

Clean Thoroughly: Remove debris to prevent friction, especially in wet drilling conditions.

Sharpen or Replace: Resharpen tips or replace bits to maintain cutting efficiency.

Store Properly: Keep in a dry environment to avoid corrosion of carbide rock drill bits.

Maintenance can extend bit life by up to 25%, reducing costs in rock drilling bits applications (Holmberg et al., 2017).