Mining drills are the backbone of modern mining operations, enabling the extraction of valuable minerals from the earth’s toughest surfaces. From underground tunnels to open-pit quarries, these powerful machines break through rock, concrete, and stone with precision and efficiency. Litian Heavy Industry Machinery Co., Ltd, a leading manufacturer of rock drilling tools, plays a pivotal role in this process by providing high-quality components like shank adapters, drill rods, and button bits. But how exactly do mining drills work, and how do Litian’s tools enhance their performance? In this article, we’ll explore the mechanics of mining drills, their key components, and the role of advanced tools in optimizing drilling operations.

Mining drills operate by penetrating rock through mechanical forces, typically using percussion, rotation, or a combination of both. The process involves creating a hole in the rock to extract core samples for exploration, facilitate blasting, or access mineral deposits. According to industry insights, drilling is essential for both exploration (to identify mineral deposits) and production (to extract resources). The primary types of mining drills include hydraulic top hammer drills, pneumatic drills, and rotary drills, each suited to specific rock types and applications.

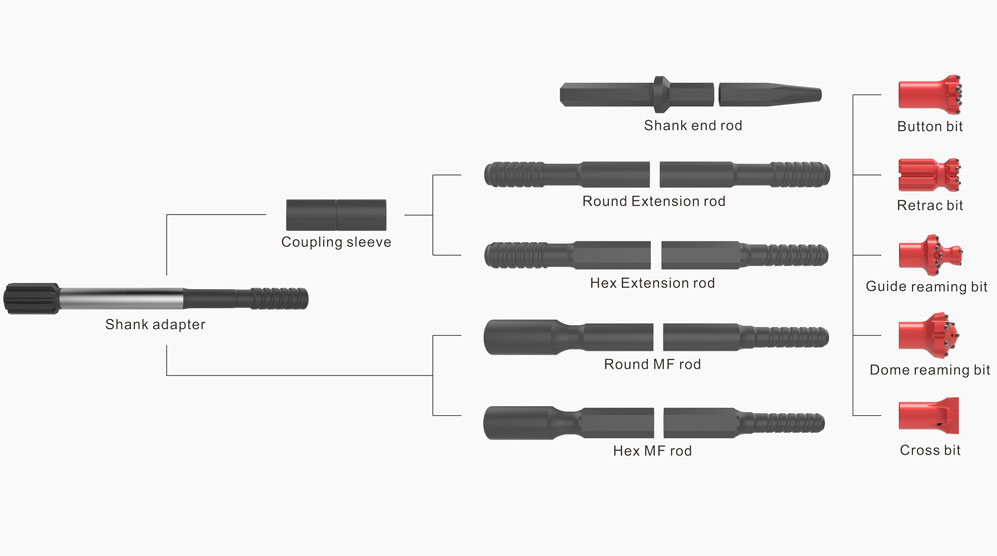

A mining drill is a system comprising several critical components, each working together to achieve efficient rock penetration:

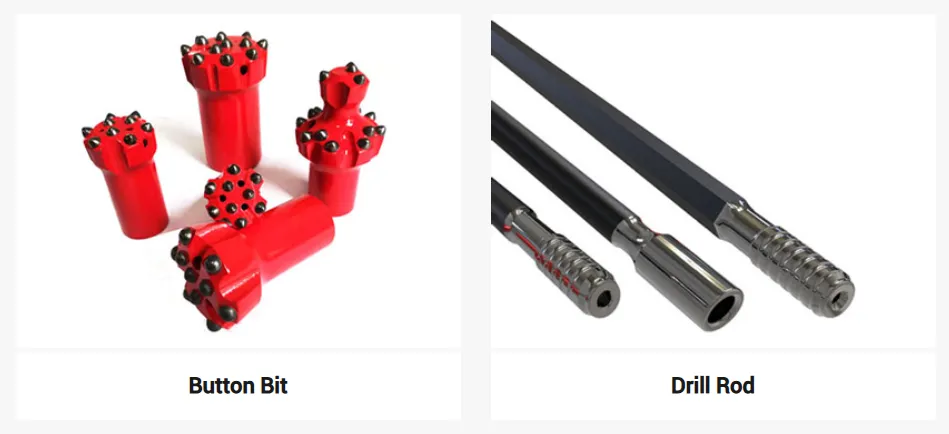

Drill Bit: The cutting tool that directly contacts the rock, fragmenting it through percussion or rotation. Litian's threaded button bits, for example, are designed for medium to hard rock formations, offering superior abrasion resistance.

Drill Rod: Transfers energy from the drill to the bit. Litian's high-quality drill rods ensure minimal energy loss during transmission.

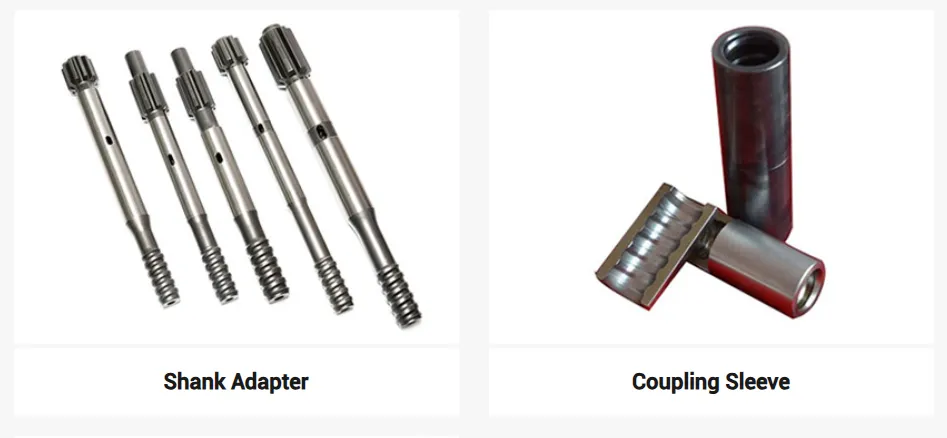

Shank Adapter: Connects the drill rod to the rock drill, absorbing impact energy and torque. Litian's shank adapters, made from high-quality alloy steel with carburizing treatment, are compatible with brands like Atlas Copco, Sandvik, and Furukawa.

Power Source: Converts electrical, hydraulic, or pneumatic energy into percussive or rotational force. Hydraulic top hammer drills, like those supported by Litian's tools, are popular for their robustness in hard rock.

Drill Rig: The mounting platform (track or tire-mounted) that positions and stabilizes the drill. Jumbo drills, for instance, use flexible booms to direct the drill bit accurately.

The drilling process begins with the drill bit applying compressive or shear forces to the rock, causing it to fracture. In percussion drilling, the bit strikes the rock repeatedly (up to several times per second), creating cracks that propagate outward. The bit is indexed (rotated slightly) after each strike to ensure consistent penetration. In rotary drilling, the bit grinds through softer materials by rotating at high speeds. Compressed air or water flushes out rock cuttings (debris) through the drill string, keeping the hole clear and preventing bit wear.

Litian's top hammer drilling tools, such as their button bits and shank adapters, are designed to optimize this process. Their bits handle diverse rock conditions, from soft to extremely hard, while their shank adapters ensure tight connections and efficient energy transfer, reducing wear and enhancing drilling speed.

Mining drills vary based on their method of penetration, power source, and application. Here are the main types:

Hydraulic Top Hammer Drills: Use a piston to deliver high-frequency impacts to the bit, ideal for hard rock. Litian's shank adapters, like the T38 and T45, are tailored for top hammer drills from brands like Sandvik (HL series) and Atlas Copco (COP series).

Pneumatic Drills: Powered by compressed air, these are used for softer rocks or smaller-scale operations. They require more operator skill but are less powerful than hydraulic drills.

Rotary Drills: Employed in softer materials or exploration, using rotation to grind through rock. Diamond core drills, for instance, extract cylindrical core samples for geological analysis.

Down-the-Hole (DTH) Drills: Feature a hammer at the bit, delivering direct impacts to the rock, ideal for deep, large-diameter holes in quarries or open-pit mines.

Litian supports these drill types with high-quality components, ensuring compatibility and performance across applications like tunneling, quarrying, and underground mining.

Litian Heavy Industry, founded in 2008 and based in Huludao, China, is a trusted manufacturer of rock drilling tools, including shank adapters, drill rods, and button bits. Their products are designed to enhance drilling efficiency by:

Improving Durability: Litian's shank adapters undergo carburizing and advanced CNC machining, ensuring wear resistance and a lifespan of 500–2,000 hours in demanding conditions.

Ensuring Compatibility: Their tools are compatible with major rock drill brands, such as Atlas Copco (COP1838), Sandvik (HLX5), and Montabert (HC series), offering versatility across equipment.

Reducing Costs: By optimizing energy transfer and minimizing wear, Litian's tools lower maintenance and replacement costs, as highlighted in their case study of the Fangxi Water Diversion Tunnel project.

Supporting Diverse Applications: Litian’s tools are used in tunneling, mining, quarrying, and hydropower projects, with custom designs available for specific geological conditions.

| Component | Function | Litian’s Contribution |

|---|---|---|

| Drill Bit | Fragments rock through percussion or rotation | Threaded button bits for hard rock drilling |

| Drill Rod | Transfers energy from drill to bit | High-quality rods for minimal energy loss |

| Shank Adapter | Connects drill to rod, absorbs impact and torque | Carburized alloy steel adapters for durability |

| Power Source | Converts energy into percussive/rotational force | Supports hydraulic and pneumatic systems |

| Drill Rig | Positions and stabilizes the drill | Compatible with major rig brands |

To maximize the efficiency and lifespan of mining drills, consider these tips:

Choose the Right Bit: Select a bit suited to the rock type (e.g., Litian’s button bits for hard rock or chisel bits for softer rock).

Regular Maintenance: Clean and lubricate shank adapters and rods after each use to prevent wear, as recommended by Litian.

Adjust Parameters: Match propulsion pressure to rock hardness to avoid excessive stress on components.

Use Quality Tools: Opt for high-performance components from trusted manufacturers like Litian to ensure durability and compatibility.

Monitor Flushing: Ensure proper air or water flushing to remove cuttings and reduce bit wear.

Litian's commitment to quality and innovation sets them apart in the mining industry. Their 27,000-square-meter production facilities and high-tech manufacturing processes ensure precise, durable tools. Their shank adapters, for instance, feature advanced thread technology and corrosion-resistant coatings, making them ideal for harsh environments like wet mines or abrasive quarries. By working closely with customers, Litian tailors solutions to specific geological conditions, as seen in projects like the 8,319-meter Fangxi Water Diversion Tunnel in Serbia.

Mining drills work by combining percussive or rotational forces to penetrate rock, with key components like drill bits, rods, and shank adapters ensuring efficient energy transfer. Litian Heavy Industry enhances this process with high-quality, durable tools designed for compatibility with leading rock drill brands and diverse applications. By choosing Litian's shank adapters, drill rods, and button bits, operators can achieve faster drilling, lower costs, and improved safety.

This is the first one.