Tunnel Boring Machines (TBMs) are engineering marvels that drive tunnel construction for subways, railways, highways, and hydropower projects through diverse geological conditions. The TBM cutter head, equipped with TBM disc cutters, is the core component responsible for excavating rock, stabilizing the tunnel face, and managing muck. This article explores the tunnel boring machine working principle, focusing on how TBM cutters function, their strategic arrangement, wear management challenges, and future trends in TBM engineering, providing insights into how Tunnel Boring Machines work and their critical role in modern tunneling.

The TBM cutting head relies on TBM disc cutters to break rock through a dynamic interplay of forces, central to the Tunnel Boring Machine operation. Each TBM disc cutter engages the rock in three primary ways:

Normal Pushing Force: Directed toward the excavation surface, this force is driven by the TBM's hydraulic thrust system, pressing the cutter ring into the rock. High-quality cutters, like those designed for hard rock cutter head applications, ensure consistent penetration in tough formations.

Tangential Rolling Cutting Force: Aligned with the cutter's tangential direction, this force results from the cutter head's torque, allowing the cutter to shear rock as it rolls. Precision-engineered cutter rings optimize this action, reducing energy loss in rock tunneling machine projects.

Lateral Force: Generated by the cutter's squeezing action and the cutter head's rotation, this force is minor, pointing toward the center of the TBM head, and is typically negligible compared to the other two.

As the cutterhead TBM rotates, each TBM cutter revolves around the cutter head's axis while spinning on its own, carving concentric grooves on the tunnel face. This process induces extrusion, shear, and tensile cracking, producing muck composed of crushed rock, fragments, and powder. The muck's composition varies based on rock properties, cutter geometry, thrust pressure, and cutter spacing. Advanced TBM disc cutters, such as those from Litian Heavy Industry, use carburized alloy steel to ensure durability and efficiency in both soft rock cutterhead and hard rock cutter head scenarios, supporting seamless tunnel cutting.

The arrangement of TBM cutters on the cutterhead is a critical aspect of TBM cutter head design, ensuring balanced forces and efficient rock breaking. The layout must adhere to mechanical and geometric principles:

Balanced Force Distribution: TBM cutters are positioned to minimize radial loads on the cutterhead’s bearings, enhancing durability. Spiral patterns, often single or double, ensure uniform stress distribution, vital for shield Tunnel Boring Machine applications.

Sequential Rock Breaking: Front cutters create initial grooves, setting up rear cutters for progressive breaking. Phase differences between adjacent cutters facilitate this sequence, improving TBM process control.

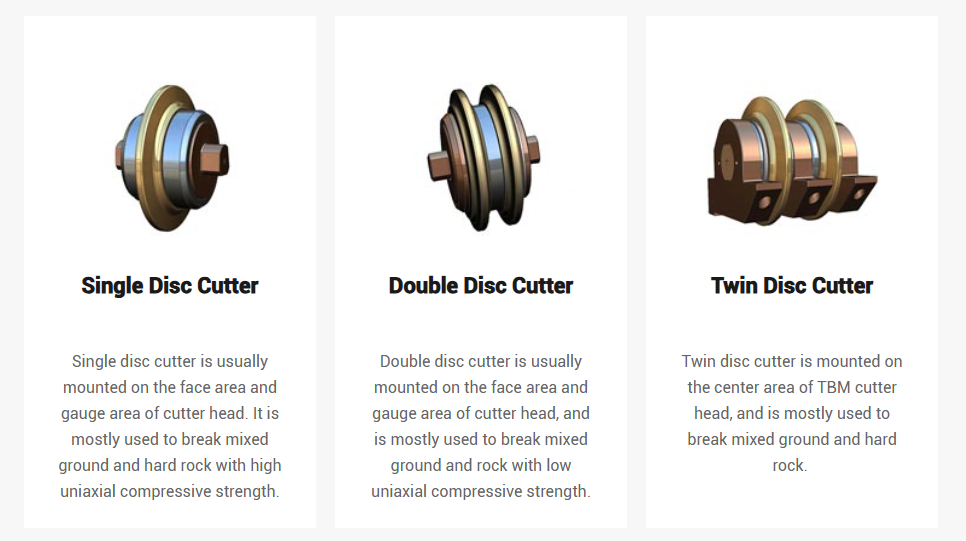

Cutter Type Selection: Single TBM disc cutters are preferred for face and gauge positions to ensure even wear, while double or triple TBM disc cutters are used in the center to optimize space. Gauge cutters, located on the outer edge, face high wear due to their speed, requiring robust designs.

Cutter spacing, a key element of TBM cutter head parts, is determined by two approaches:

Fixed Spacing with Variable Thrust: Maintains consistent spacing and adjusts thrust to match rock strength, widely used for its simplicity in TBM work.

Variable Spacing: Modifies cutter numbers or ring configurations to adapt to geological variations, ensuring flexibility in mixed strata.

Optimal spacing ranges from 50–120 mm, with smaller spacing for hard rock and larger for soft rock, as seen in TBM mineria projects.

Wear management is a significant challenge in TBM drilling machine operations, as TBM disc cutters endure intense abrasion and impact in diverse geological conditions. Effective strategies are essential to extend cutter life and minimize downtime:

Wear Monitoring: Regular inspections detect wear, cracks, or deformation, particularly in gauge TBM cutters, which experience high-speed abrasion. Durable TBM cutter head parts are designed to withstand tough conditions, but daily checks prevent failures.

Debris Management: Removing muck and debris reduces friction-related wear. Efficient flushing systems, supported by robust TBM cutter designs, ensure clean boreholes during tunnel cutting.

Replacement Planning: Timely replacement of worn TBM cutters prevents uneven force distribution, which can damage the cutterhead machine. Modular TBM cutter designs simplify cutter head intervention, reducing project delays.

Operational Adjustments: Tuning thrust and torque to match rock conditions extends cutter life. For instance, lower thrust in hard rock minimizes stress, aligning with the principle of boring machine efficiency.

Proper wear management can extend TBM cutter life by 20–30%, reducing costs in TBM tunnel machine projects. Litian's alloy cutter head designs, with wear-resistant materials, have proven effective in high-profile tunneling projects, maintaining performance over extended periods.

The future of TBM engineering is shaped by innovations that enhance efficiency, sustainability, and adaptability. Emerging trends in TBM cutter head design include:

Smart Sensor Integration: By 2025, sensors embedded in TBM disc cutters monitor wear, temperature, and vibration in real-time, enabling predictive maintenance to prevent failures during TBM work.

Eco-Friendly Materials: Advances in recyclable alloys and low-friction coatings reduce environmental impact, aligning with sustainable Tunnel Boring Machine process control.

Automated TBM Systems: Automated TBM cutter adjustments and AI-driven drilling optimization improve precision in how a Tunnel Boring Machine works, particularly in mixed strata.

Enhanced Durability: Next-generation TBM cutters use advanced composites to withstand extreme conditions, supporting both soft rock cutter head and hard rock cutter head applications.

These trends drive the evolution of how Tunnel Boring Machines work, with manufacturers like Litian Heavy Industry contributing through precision-manufactured TBM cutters. Compatible with major TBM brands like Herrenknecht and Robbins, Litian's cutters incorporate wear-resistant alloys, supporting cutting-edge tunnel projects worldwide.

| Aspect | Description | Impact on TBM Performance |

|---|---|---|

| Material | Alloy steel with carburizing | Enhances durability in hard/soft rock |

| Cutter Arrangement | Spiral layouts for sequential breaking | Improves force balance and efficiency |

| Spacing Design | 50–120 mm, tailored to rock type | Optimizes rock breaking in mixed strata |

| Wear Management | Inspections, cleaning, timely replacements | Extends cutter life, reduces downtime |

| Future Innovations | Smart sensors, eco-friendly materials | Boosts precision and sustainability |

The TBM cutter head, powered by TBM disc cutters, is central to how does a Tunnel Boring Machine work, enabling efficient excavation through complex rock-breaking mechanisms and strategic layouts. By addressing wear management and embracing innovations like smart sensors, the industry continues to advance tunnel cutting machine performance. High-quality TBM cutters, such as those from Litian Heavy Industry, enhance durability and efficiency in subway, railway, and hydropower projects。