In drilling operations, "reamer drill bits" (or simply reaming bits) come in various forms depending on the industry. The term often causes confusion: top hammer reaming bits used in mining and quarrying are designed for rock, while precision reamers in metalworking enlarge holes in metals like steel or aluminum.

This guide clarifies if rock drilling reamer bits can be used for metal drilling, highlights key differences, and provides selection advice for optimal results.

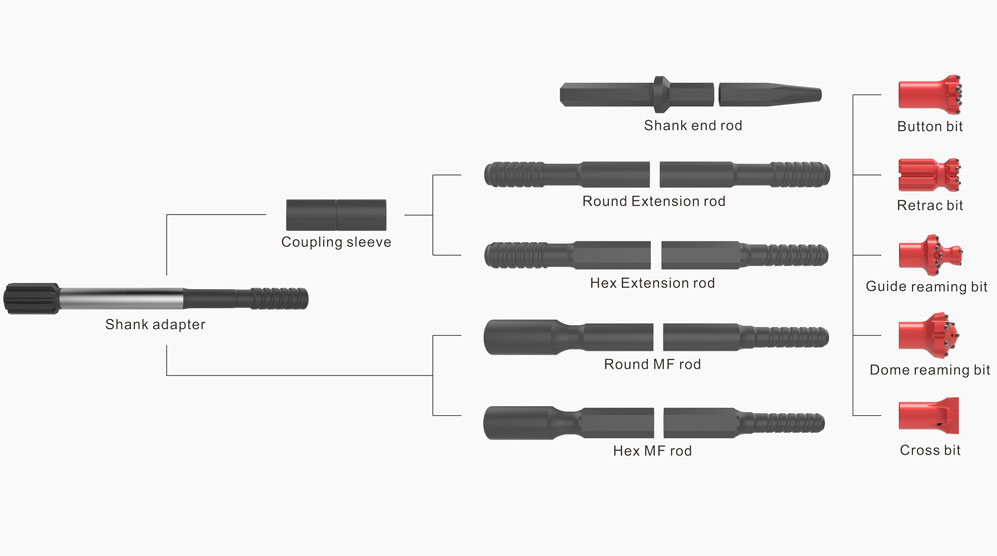

In top hammer drilling (common in mining, quarrying, and tunneling), reaming bits enlarge pilot holes in hard rock formations.

Pilot reaming bits: Create initial smaller holes for alignment.

Dome reaming bits: Follow to expand to larger diameters (e.g., 76-152mm).

Tungsten carbide buttons for impact crushing rock.

Threaded connections (R32, T38, T45).

High-impact percussion from hydraulic/pneumatic drifters.

These bits excel in abrasive, hard environments but are not optimized for soft or ductile materials.

In metalworking, reamers are precision finishing tools for enlarging pre-drilled holes in metals.

Fluted (straight or helical) cutting edges for minimal material removal (0.005-0.03 inches).

High-speed steel (HSS) or carbide for smooth finishes.

Used in drill presses, lathes, or CNC machines at controlled speeds.

Reamers achieve tight tolerances and superior surface finish in materials like steel, aluminum, or brass.

No, rock drilling reamer bits (like top hammer types) are generally not suitable for metal drilling. Here's why:

Design Mismatch: Rock reamers use aggressive carbide buttons for percussive crushing—effective on brittle rock but likely to cause excessive vibration, poor finish, or tool damage in ductile metals.

Material Removal: Rock bits remove large volumes aggressively; metal reamers remove tiny amounts for precision.

Risks: Using a mining reamer on metal could lead to oversized holes, rough surfaces, chipping, or bit failure due to differing hardness and ductility.

Exceptions: In rare heavy-duty scenarios (e.g., thick structural steel), adapted tools might work, but dedicated metal reamers are always recommended for safety and quality.

| Aspect | Rock Drilling Reaming Bits (Top Hammer) | Metalworking Reamers |

|---|---|---|

| Primary Material | Hard/abrasive rock (granite, basalt) | Metals (steel, aluminum, brass) |

| Cutting Mechanism | Percussive impact with carbide buttons | Rotary cutting with flutes |

| Material Removal | High volume for enlargement | Minimal (finishing only) |

| Typical Diameters | 64-152mm | Smaller, precise (e.g., 1/8" to several inches) |

| Equipment | Hydraulic top hammer rigs | Drill presses, lathes, CNC machines |

| Finish Achieved | Functional borehole walls | High-precision, smooth surfaces |

| Best For | Mining, quarrying, tunneling | Machining, manufacturing, assembly |

For Rock/Mining Applications: Use top hammer reaming bits sequentially (pilot then dome) for efficient hole enlargement in hard formations.

For Metal Applications: Opt for machine or hand reamers after drilling a slightly undersized hole (2-4% smaller).

Hybrid Needs: Some industrial tools combine drilling/reaming for metal, but never substitute mining bits.

Always match the tool to the material for safety, efficiency, and longevity.

Prepare a pilot hole first.

Use adequate coolant/flushing.

Monitor speeds/feeds based on material.

Inspect for wear regularly.

Rock drilling reamer bits are specialized for tough geological conditions and cannot effectively or safely replace precision reamers for metal drilling. Confusing the two can lead to poor results and tool damage. For metal projects, dedicated machining reamers ensure accuracy and finish; for rock, stick to top hammer designs.

Understanding these distinctions helps professionals select the right tool for the job.

Epiroc Rock Drilling Tools Handbook (epiroc.com)

Sandvik Mining and Rock Technology: Top Hammer Tools Guide (rocktechnology.sandvik)

Kennametal: Reaming Tool Basics and Tips (kennametal.com)

Robit Plc: Top Hammer Drilling Consumables Overview (robitgroup.com)

This is the first one.