Project: Zhejiang Jinyun Pumped Storage Hydropower Project

Cooperation Unit: China Water Resources and Hydropower 14th Engineering Bureau Co., Ltd.

Introduction: Zhejiang Jinyun Pumped Storage Hydropower Project is the first single CNY 10 billion investment project in Lishui City. The hydropower's pivot building is mainly composed of upper reservoir, drain pants, water delivery system, underground powerhouse, and ground switch station. It is a daily regulated pumped storage power station with a designed annual power generation capacity of 1.8 billion kWh. The upper reservoir has a total storage capacity of 12.62 million m³ and the lower reservoir has a total storage capacity of 15.3 million m³. The total construction period is 95 months. It is planned to be fully operational for power generation in 2026.

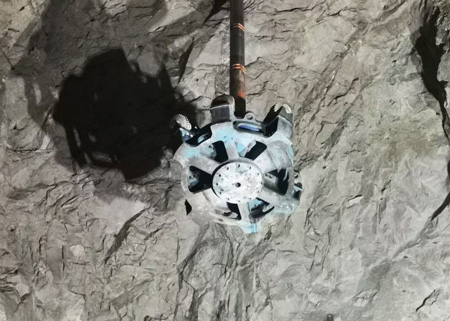

The main powerhouse was officially excavated on August 20, 2020. The project will use large-diameter raise boring rigs, tunnel boring machines and other advanced equipment for underground cavern construction.

On June 8, 2021, the 384-meter-long directional drilling pilot hole of the No. 1 diversion well was successfully penetrated. The inclined well is carried out by drilling and blasting the hole from top to bottom by installing raise boring rigs from the bottom.

Product Supply; Raise boring cutters 13 inch

Supply Time: From August 2020 to present

Quality Requirements:

①Seal: Trelleborg seal is used, and the seal must have excellent high-temperature resistance (seal high-temperature resistance ≥260℃), reliable sealing performance, and meet long-distance use in harsh working environments, and no oil leakage or no mud entering due to seal failure.

②Bearings: TIMKEN bearings are used, which must have excellent performance and reliable operation (bearing running time≥700h).

③Hub: using reasonable design, using high-quality materials, with appropriate hardness (hub hardness 48-52HRC), which can meet the long-distance use under the geological conditions of this section, without cutter hub damage, deformation, and serious wear.

④Cutting head: single cutting head axial force and longitudinal force ≥30T, alloy buttons hardness 65-75HRC, alloy button wear is not more than 1/3. If appear to take off buttons, broken buttons, regard as unqualified.

⑤The starting torque of the cutters is set reasonably (10-15), and there should be no abnormal conditions such as uneven wear of the cutter ring caused by the unreasonable starting torque setting.

Jan 23-2026

How to Choose the Best Drill Rod Factory

Jan 18-2026

Core Drilling in Mining vs Construction